This post concerns the Open ARDF Equipment Project, which is utilizing the Receiver Development Platform, both of which are being developed together.

With the basic components for serial communications and bootloading identified and verified experimentally, it was time to take another look at the schematic. Only the transmitter schematic has been updated, but as far as the USB/FTDI changes are concerned, the same circuitry will go into the receivers as well.

Since changes were being made to the schematic anyway, it seemed like a good time to examine the transmitter’s DC-power control circuitry. Below is a summary of the transmitter schematic changes that were made, and the features those changes support. Schematics have been posted.

DC-POWER CHANGES

Master On/Off Switch – A single SPST switch was added. Turning it off removes all LiPo/Li-Ion battery power going to the transmitter, while still allowing the battery to be charged via USB.

Direct Processor Power – The processor is continuously powered directly from the LiPo/Li-Ion battery as long as master power is turned on. There is no provision for powering off the processor except via master on/off.

Processor Power Control – The processor is given the means to shut down all power to every part of the transmitter, except for the processor itself. Thus the processor is in full control of current drain, and should be able to bring the total current drawn below 1mA by shutting down all devices under its control, and putting itself into a low-power sleep mode.

Processor Wake-Up – Even in a deep-sleep low-current mode, the processor can be awakened by an interrupt received from the real-time clock. The processor can schedule an alarm time (e.g., competition start time) at which to be awakened.

Antenna Disconnect Protection – Provision has been made to automatically shut down all power to the transmitter (except to the processor) in the event that the antenna is disconnected. This will prevent the transmitter from being damaged by operating into an absent antenna, and is also intended to be the primary way to turn on/off the transmitter when it is deployed or collected: just plug in the antenna and you’re all set.

USB-to-UART CHANGES

The following features are supported by the FTDI circuit changes applied in the schematic:

Processor Power from USB – Even if the master power switch is in the off position, connecting the transmitter to a USB power source will power up the processor. This way it will always be possible to bootload, or change transmitter settings, via USB even if the transmitter is powered off.

FT232R Device Optional – The builder can decide whether or not to populate the FT232R USB-to-UART IC. The option to instead use an “FTDI Cable” (like this one) is supported by the inclusion of a 6-pin male header.

USB Compliance – Circuitry has been added to ensure that the transmitter draws no more than the USB standard-specified current and prevents excessive surge current.

LED Data Indicators – Red and green LEDs indicate when data is flowing on the serial data lines.

Cloning – It will be possible to “clone” transmitters by connecting their serial ports using a “null modem” cable. This will allow any transmitter to be designated as “master”, and by connecting it with another “slave” transmitter will synchronize the slave’s clock, and configure the slave to operate of the appropriate frequency and sport mode. This should eliminate the need for a Control Head, or a PC, in many situations once a single transmitter (the master) has been configured.

Hardware UI

This transmitter design incorporates a simple interface for the user: a push button, an LED, and a power switch. Additional feedback to the user can be accomplished via radio, by having the transmitter send pico-power transmissions (with the power amplifier turned off), that can be monitored up to a few meters away using a handheld receiver. The intent is for these to be used for basic configuration settings (such as “fox number” and activity type), and to trigger status feedback from the transmitter.

The serial interface should make it easy to configure any setting, including “call sign”, clock synchronization, automatic start time, and every other function and feature the transmitter provides. A program running on a PC/Mac/Ubuntu will provide a simple and intuitive graphical user interface, or menu-driven format. In a future version, an app running on a smartphone could provide the interface and configure the transmitter conveniently over WiFi. The button and LED is for those times when a computer is impractical or unavailable.

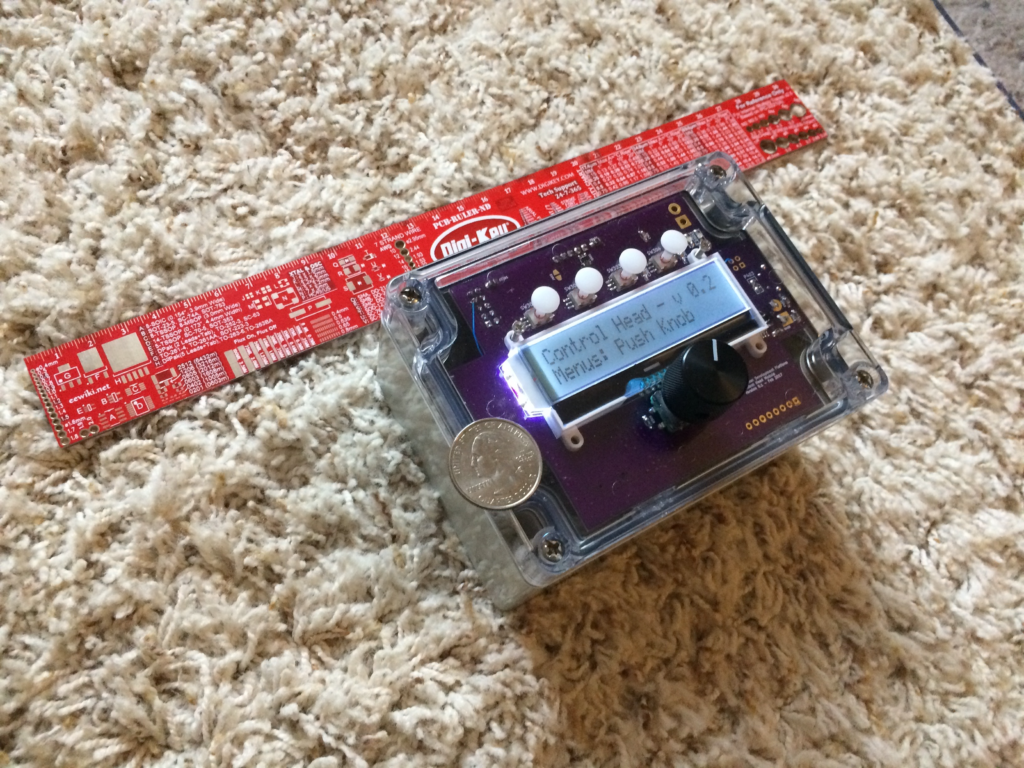

The ruler and quarter provide a sense of scale: the box is easily held in one hand, but it fills the hand. The box is large enough to hold the entire 2-band receiver, and a battery. The four white dots are the button plungers mentioned above, and serve as the “menu” buttons. The black knob below the display operates the rotary encoder, which can be pressed to activate a fifth button.

The ruler and quarter provide a sense of scale: the box is easily held in one hand, but it fills the hand. The box is large enough to hold the entire 2-band receiver, and a battery. The four white dots are the button plungers mentioned above, and serve as the “menu” buttons. The black knob below the display operates the rotary encoder, which can be pressed to activate a fifth button.